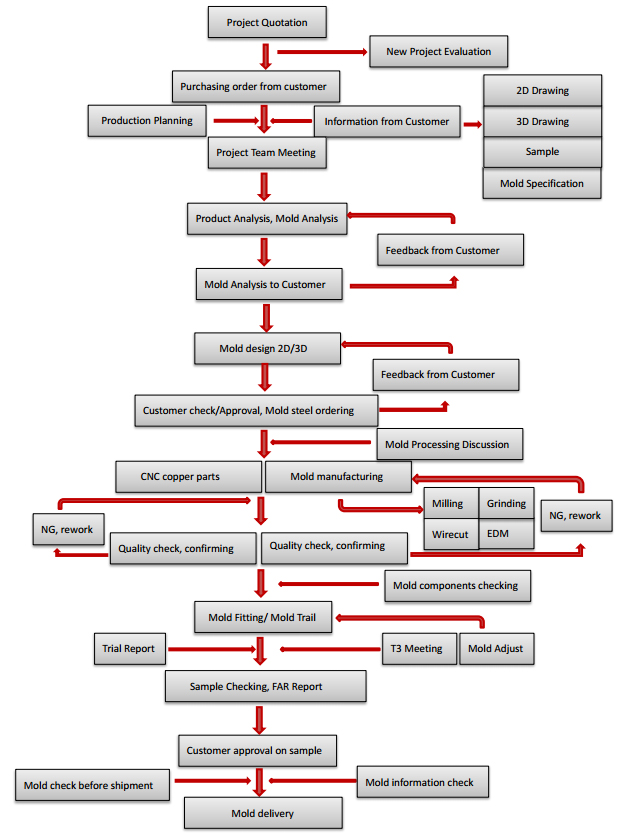

Injection Mold Project Workflow

Project Initiation

Receive customer requirements and specifications.

Conduct initial project review and feasibility analysis.

Design Phase

Create 3D CAD models of the product and mold.

Perform mold flow analysis (CAE) to optimize design.

Finalize mold design and engineering drawings.

Material Procurement

Purchase mold steel and standard components.

Conduct Incoming Quality Control (IQC) for materials.

Mold Manufacturing

CNC machining, EDM, and other precision processes.

In-Process Quality Control (IPQC) at each manufacturing stage.

Mold Assembly

Assemble all mold components.

Verify dimensions and functionality.

Mold Testing & Trial

Conduct trial injections to test mold performance.

Inspect molded parts for quality and accuracy.

Final Inspection & Approval

Perform Outgoing Quality Control (OQC).

Verify compliance with customer requirements.

Delivery & Support

Ship the mold to the customer.

Provide on-site support for mold setup and production.

Post-Production Services

Regular maintenance and troubleshooting.

Continuous improvement based on customer feedback.

Privacy PolicyCopyright © Taizhou Jusheng Mould and Plastic Co., Ltd. All Rights Reserved.